3 phase separator retention time calculation

The seam-to-seam length, Lss, for the horizontal vessel should be determined from the geometry once a diameter and effective length have been determined. 4-Calculation based on input data as following: a- Separator dimension as per manufacturer documents, diameter in inch, length in ft. b- Liquid production as per SWT operator in bb/d. L/D ratio Table 12. Step 3. In the end of this post, I share free spreadsheet on how to size horizontal three phase separator. Last calculate the boot dia and length (easiest one) Actually Three phase separator design is very critical and could not be described and explained in a few lines unless you start working on it. Retention time utilizes time to aid separation. Already a member? To calculate (liquid) retention time for a two-phase separator divide the liquid volume inside the vessel by the liquid flow rate, these values are normally in the range 1-3 minutes depending from application. This grouping directly affects the selection of the L/D ratio in the early stage of the design separator. The ratio of height to diameter is typically in the 3 to 5 range for two-phase separators. Table 1 shows physical properties of three phase and the mass flow rates at the inlet.

It should be noted that the times between levels requirements for the oil phase are more onerous than for the water phase as it is the combined (oil + water) flow rates that are used for the levels in the oil zone, whereas just the water flow rate is used for the levels in the water zone. Sizing the water phase by oil-drop removal is usually not effective. It is important to note, there are 3 key ways to separate oil and water including: chemical, heat and time. AH) eR p' pl/[ Copyright 1998-2023 engineering.com, Inc. All rights reserved.Unauthorized reproduction or linking forbidden without expressed written permission.

A more analytical approach was described, and the following base case example illustrates the methodology. Perrys Chemical Engineers Handbook, fifth edition, 5-66. The given values for Example 3 are listed next: Step 1. If either of the following conditions applies, the vessels shall be constructed in accordance with Division 2, unless otherwise approved by the Company.

2- Minimum retention time as per API 012J: a- Paragraphs: C.1.3, 4, 5,6, 7 & 8for two phases separator. This relationship is also given by an inlet momentum criterion as mVm2 = C2, where C is given as 100 for continuous service and 125 for intermittent service. aL) |-S Step 8: Calculate slenderness ratio (12 L ss Table 7 shows liquid levels for different vessel diameters. Calculate the height for liquid retention time with Eq.

The selected vessel would then be 24 in. WebThere is a procedure to design three phase separators .

aH) A R Table 7.

8. M#G"@PrNZK!_,_#x^e+'ak;Z9fr$ endstream endobj 53 0 obj 1064 endobj 43 0 obj << /Type /Page /Parent 5 0 R /Resources << /Font 56 0 R /XObject << /im5 44 0 R /im6 48 0 R >> /ProcSet 2 0 R >> /Contents [ 46 0 R 50 0 R 52 0 R ] >> endobj 56 0 obj << /F0 6 0 R /F1 30 0 R /F3 36 0 R /F4 38 0 R /F5 40 0 R /F6 54 0 R >> endobj 60 0 obj << /Length 61 0 R /Filter /FlateDecode >> stream 1Three-phase flow patterns (Keskin et al. In addition, the API RP14E[1] on erosion velocity should be included. >+I2}R60 x)pM"8XCspW0]jOkXuJ}'++CXq@r{]puquIbi]/V2a!/9+psfF]AXt8q72>bT}(nQklcQ|!n-hv2hKIai:5ZYLb ]oGL=T7y%`n@V-g#8XNg7!#N9%@bN& !|]dhTNWn9YEqFZF~c|"a7dtsQ\Hqt eF PPZ:,_BsqE2{1Jektx2GU0_5|8#x# e1'CeM~)yzGgo7wJTZyf`BW%* "Knowledge" is only found through the accumulation and analysis of data.

Recommended K value 41 .

The assumed submerged weirliquid-handling configuration. Example 1: vertical two-phase separator with a mesh pad demister given values, Example 2: Horizontal two phase separator, Example 3: Vertical three phase separator. In horizontal vessels, a simple ballistic model can be used to determine a relationship between vessel length and diameter. aL)0_(,R Fig. Click Here to join Eng-Tips and talk with other members!

13.4-ft separator satisfies the requirements, so you would round up to an 84-in. It is important to note, there are 3 key ways to separate oil and water including: chemical, heat and time. Good contents.Keep the good work for upcoming article. Example of separator selection 48 0.8 3.7 6.2 1.6 42 0.9 4.9 7.4 2.1 36 1.1 6.6 9.1 3 He holds a BS in chemical engineering from Lakehead University in Thunder Bay, Ontario, Canada, and a diploma in natural gas and petroleum technology from the British Columbia Institute of Technology in Vancouver, BC, Canada. Similarly for vertical vessels, the relationship of vessel diameter and liquid pad heights is given by Eq. Seam-to-seam length for various retention time.

Yeremias K Lusi is a young-highly motivated engineer who once worked as a mechanical & piping engineer in a technical consultant company. aL) |-S Fig. More information. AH) _ /B Determine oil cross-sectional area based on settling theory or empirical correlations by following similar procedure in Steps 1 and 2. The approach used here, and in the Excel spreadsheet, is approximate only.Regarding Item 4, the effective release point, the same assumption has been made for all inlet types: the dispersed phase is released uniformly over the vertical height of the continuous phase at the centerline axis of the vessel at the start of the gravity separation sectionbasically at the perforated plate location. aH) A R Meanwhile, three-phase separators are used to separate gas from crude oil and water component. To ensure that the liquid and gas reach equilibrium at separator pressure, a certain liquid storage is required.This is defined as retention time or the average time a molecule of liquid is retained in the vessel, The no inlet device configuration as shown would not be used in a horizontal vessel. Save my name and email in this browser for the next time I comment. In this case you have to calculate the curve area.

%PDF-1.3 These are typically perpendicular plates, as shown in Fig.

Step 2. Two-phase separators are used to separate gas from the total liquid stream. ! AH)%%$8N @/P aS 5). A design review of an oil and gas project is a comprehensive evaluation of the technical design and engineering of the project, aimed at identifying any potential issues or risks that could impact Hi There! In Part 1 of this series, the author noted that historically, the sizing of three-phase separators, in particular for oil/water separation, has been based on the specification of residence time criteria, which is an imprecise method as residence time alone fails to capture many of the parameters/variables that clearly should have an impact on liquid/liquid phase separation performance, such as feedpipe conditions, inlet device type, phase flow distribution inside the separator, vessel length/diameter ratio, fluid properties, and dispersed phase droplet sizes. Calculate vessel diameter and length with Eq. AH) eR p' pl/[ In this case you have to calculate the curve area.

"(($#$% '+++,.3332-3333333333 " The operating pressure and temperature are set to 1 bar and 20C, respectively. 28 was chosen to allow for an easy solution of Eq. *Eng-Tips's functionality depends on members receiving e-mail. An example illustrates the calculations needed to achieve the specified outlet fluid qualities. AH)0S *:JZjz ? AH)0S0S

Therefore, in some kinds of literature, separators could be categorized according to their operating pressure.

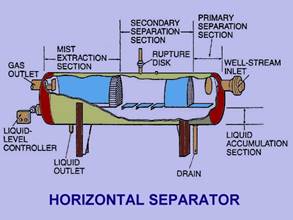

didikurniadi03@gmail.com, Cased hole logging engineer, Well test supervisor, DAQ engineer , Sampling engineer and Gauge man. Table 9. Retention time for 3 phase separation in horizontal separators, Low-Volume Rapid Injection Molding With 3D Printed Molds, Industry Perspective: Education and Metal 3D Printing. Determining Settling Rates of Particles. From a process design perspective, the 3-Phase separator is typically similar to the 2-phase separator, but with additional internals to handle two immiscible liquids (oil and water) rather than one liquid. In general, the 3-phase horizontal separator settler consists of three-zone compartments that automatically determined the internals type selection and installation. Table 1 shows physical properties of three phase and the mass flow rates at the inlet. aL) |-S aL) S

This button displays the currently selected search type. It is also called as free-water-knockout. B &9nS&x&=^0!|"Dn`lm&fkpY)[$A3dEf|F

"(($#$% '+++,.3332-3333333333 Figs. vol", b- If SETTLING volume not known go to tap "Unknown Setl.

2007).

5). "(($#$% '+++,.3332-3333333333 " Table 10. Step 3. The most common retention time ranges from 3 minutes to 30 minutes, depends on laboratory and field data. Two, a cylindrical box with a 15-in. aH) A R When expanded it provides a list of search options that will switch the search inputs to match the current selection. You must log in to edit PetroWiki. a !1AQa"q2B#$Rb34rC%Scs5&DTdEt6UeuF'Vfv7GWgw(8HXhx )9IYiy aL) S 1Three-phase flow patterns (Keskin et al. a !1AQa"q2B#$Rb34rC%Scs5&DTdEt6UeuF'Vfv7GWgw(8HXhx )9IYiy 3-Phase separator in horizontal orientation consists of a shell, dished ends, and mostly two saddles. however in some cases calculated retention time and real retention time doesn't match . a !1AQa"q2B#$Rb34rC%Scs5&DTdEt6UeuF'Vfv7GWgw(8HXhx )9IYiy 1Three-phase flow patterns (Keskin et al. Determine vessel diameter based on cross-sectional area for each phase, 6. Previously, he was chief engineer with John M. Campbell and Company in Norman, Oklahoma, for 8 years. Too high of a gas velocity will result in liquid re-entrainment from the liquid surface, which may flood the demister and cause carryover. Separators are classified into two-phase and three-phase separator. For illustration, the 50% water-cut map is shown in Fig. Continue with Recommended Cookies. Olotu, C.O. WebA three-phase separator includes some internal structures such as perforated plate, coalescer and demister. Similarly, a certain amount of water storage is required to ensure that most of the large droplets of oil entrained in the water have sufficient time to coalesce and rise to the oil-water interface. Adobe d C Properties (density, viscosity) of oil and gas, respectively. Step 3. On the other hand, it is a very compact vessel.

Bothamley, M. 2013.  AL)0_BBBR

AL)0_BBBR

Low liquid level height 45 .

AL)0_BBBR We and our partners use cookies to Store and/or access information on a device. WebThere is a procedure to design three phase separators . aS Used for large surge volumes because of its most efficiency large amounts of dissolved gas are present with the liquid, The horizontal separator has a greater capacity, Can add an additional boot to achieve liquid/liquid or vapor/liquid separation efficiency, A less static head affects the supports geometry. aL)0_(,R 2.X~f61c[H$NSb.(%_@ endstream endobj 14 0 obj 94 endobj 11 0 obj << /Type /XObject /Subtype /Image /Name /im1 /Filter /DCTDecode /Width 34 /Height 1 /BitsPerComponent 8 /ColorSpace /DeviceRGB /Length 12 0 R >> stream

An example of data being processed may be a unique identifier stored in a cookie. An example of the pressurized vertical and horizontal separators used in separation & processing include: Mechanical Design of the separator is done following ASME BPVC Sec. If this data is not available, approach in table below can be used for estimation. To ensure that the liquid and gas reach equilibrium at separator pressure, a certain liquid storage is required.This is defined as retention time or the average time a molecule of liquid is retained in the vessel, Properties (density, viscosity) of oil and gas, respectively. For the past several years he has been a senior technical advisor for PetroSkills, a large technical training company that supports the oil and gas industry. Calculate Leff and Lss = Leff + d/12 for different values of d. Step 5. "(($#$% '+++,.3332-3333333333 AH)0@0S The mesh pad can be installed in two ways, if the 1.15 ft 2 is to be maintained.

9. Recommended K value Table 8.

Certainly the water viscosity is decreasing with increasing temperature (Fig.

Certainly the water viscosity is decreasing with increasing temperature (Fig.

"(($#$% '+++,.3332-3333333333 aL)0_(,R Droplet Size: 500 microns.

aH) A R *:JZjz ?

3. WebComparison of different gravity separator types Table 5. HT B^Kc=sSScS=S3sD*d(+TScfi 1 B]#HIUPp O endstream endobj 65 0 obj 83 endobj 62 0 obj << /Type /XObject /Subtype /Image /Name /im8 /Filter /DCTDecode /Width 921 /Height 1 /BitsPerComponent 8 /ColorSpace /DeviceRGB /Length 63 0 R >> stream 2.

8. The water effluent quality is more likely dictated by the added chemicals. The oil drops to be removed from the gas stream also depend upon the downstream equipment. Values for 12 Lss /d should be in the 1.5 to 3 range. d- Oil temperature inside separator as per SWT operator in deg F. e - Liquid level should be(% percentage from min. aL) S An 84-in. Liquid holdup and surge times 44 . For three-phase separators, the ratio is in the 1.5 to 3 range. Calculate vessel diameter based on gas capacity from Eq. Determination of design temperature can follow the guideline below:if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[300,250],'whatispiping_com-leader-2','ezslot_14',687,'0','0'])};__ez_fad_position('div-gpt-ad-whatispiping_com-leader-2-0'); The separation process can be described as either a 2-phase or 3-phase vessel. Purposes and Steps for the Design Review Process (PDF).

Fig.

Fig. Step 4.

Therefore, in the 3-phase separator, we will find additional control devices for controlling the liquid level (LLC) and pressure (PCV). *:JZjz ? Perry, R.H. and Green, D.W. 1984. WebTwo-Phase GasLiquid Separators. With a strong will to strengthen himself and others, he started to share his hobby through sharing knowledge and writing article. For screening purposes, the following approximations can be used, where d is the vessel diameter).

"(($#$% '+++,.3332-3333333333 " Mist Extractor / Mist Eliminator / Demister. So this is where you can find him.

AH) _ /B

aH) T-PS Retention Time. This paper for liquid retention time calculations during field operation only as a guidance.  12.5-ft separator would also be satisfactory.

12.5-ft separator would also be satisfactory.  Miedema, S.A., Vlasblom, W.J.

a !1AQa"q2B#$Rb34rC%Scs5&DTdEt6UeuF'Vfv7GWgw(8HXhx )9IYiy

Miedema, S.A., Vlasblom, W.J.

a !1AQa"q2B#$Rb34rC%Scs5&DTdEt6UeuF'Vfv7GWgw(8HXhx )9IYiy

! "(($#$% '+++,.3332-3333333333 " Produced well fluids consist of various amounts of oil, water, natural gas, and sediment. 1Approximate shell length for vertical vessels (courtesy of CDS Separation Technologies Inc.).

Two-phase separators are used to separate gas from the total liquid stream. io(A "V _/)"6MaL)`/6 AH)%%$8N$/I Similarly, a 90-in. For liquid drops in gas phase. Typical retention time for 3-phase separator 40.  a !1AQa"q2B#$Rb34rC%Scs5&DTdEt6UeuF'Vfv7GWgw(8HXhx )9IYiy The ratio of height to diameter is typically in the 3 to 5 range for two-phase separators. 10. KG_a9]}K6_9* There are one inlet and three outlets. Generally speaking, it is the requirement for the minimum distance between levels that typically has the most impact on diameter, assuming the times between levels requirements are not overly conservative. AH)0@0S Washington, DC: API. 1. However, the OIW specification is set at 2,000 ppmv and is not constraining separator size. Hi,Please refer to API Spec 12J for your guidelines and Surface Production Operations Design of Oil Handling and Facilities Vol 1 3rd Edition, Elsevier, 2008 Handbook. AH)%%$8N$/I 27; solve Eq. (Figure 4). For a 3 phase separator, the retention time is described as the total time fluid remains in the separation section at the designed flow rate. An example illustrates the calculations needed to achieve the specified outlet fluid qualities.

a !1AQa"q2B#$Rb34rC%Scs5&DTdEt6UeuF'Vfv7GWgw(8HXhx )9IYiy The ratio of height to diameter is typically in the 3 to 5 range for two-phase separators. 10. KG_a9]}K6_9* There are one inlet and three outlets. Generally speaking, it is the requirement for the minimum distance between levels that typically has the most impact on diameter, assuming the times between levels requirements are not overly conservative. AH)0@0S Washington, DC: API. 1. However, the OIW specification is set at 2,000 ppmv and is not constraining separator size. Hi,Please refer to API Spec 12J for your guidelines and Surface Production Operations Design of Oil Handling and Facilities Vol 1 3rd Edition, Elsevier, 2008 Handbook. AH)%%$8N$/I 27; solve Eq. (Figure 4). For a 3 phase separator, the retention time is described as the total time fluid remains in the separation section at the designed flow rate. An example illustrates the calculations needed to achieve the specified outlet fluid qualities.

/@CJ`kPANQIH8GL98n/m ]Q#%NG=Cfk],PCOQB9vx!pDRro_?;]noM|[cb(Vlzf!$hg7@MCCG_Ps,r\)J5II&i2'jy:]'Z1AU4sy?S0>EDRHC'vCY 8vs)\va'1g()VDUjK>

%:

j6

endstream

endobj

67 0 obj

681

endobj

57 0 obj

<<

/Type /Page

/Parent 5 0 R

/Resources <<

/Font <<

/F0 6 0 R

/F1 30 0 R

/F3 36 0 R

>>

/XObject <<

/im7 58 0 R

/im8 62 0 R

>>

/ProcSet 2 0 R

>>

/Contents [ 60 0 R 64 0 R 66 0 R ]

>>

endobj

71 0 obj

<<

/Length 72 0 R

/Filter /FlateDecode

>>

stream

"Prejudice" is having an opinion not supported by the preponderance of the data.  Please feel free to download horizontal three phase separator sizing spreadsheet.

!

Please feel free to download horizontal three phase separator sizing spreadsheet.

!

Registration on or use of this site constitutes acceptance of our Privacy Policy.

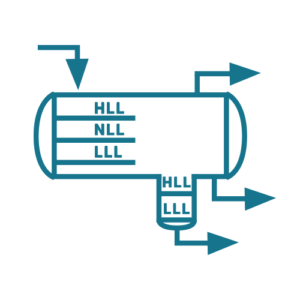

Calculate vessel height from Eq. In vertical vessels, settling theory results in a relation for the vessel diameter. You can learn the details and equations used from the book. The value of C can also vary with pipe material, solids loading, and service. The type of inlet device utilized impacts separator size and performance in four main ways: These topics have been covered earlier in this article. aL) |-S Table 8. aH) T-PS aL) S For three-phase separators, the ratio is in the 1.5 to 3 range. A three-phase separator uses gravity to separate produced well fluid into gas, oil, and water phases. AH)%%$8N$/I WebThree Phase Separators - Times Definition - Free download as PDF File (.pdf), Text File (.txt) or read online for free. It is most commonly used to separate oil, gas and free water from the fluid. Calculate liquid levels for retention time based on Eq. 1- Horizontal separator two phase and three phase only; as those are the common cases during Surface Well Test Operations.

7. Produced well fluids consist of various amounts of oil, water, natural gas, and sediment. Good started brother!I hope to see more articles from you! Liquid retention time for 2-phase separator Table 6. 2007). Table 1. Keskin et al. Manage Settings Retention time of oil and water, respectively. To size horizontal three phase separator, we need the following data: Oil rate, water rate, and gas rate. For three-phase separators, the ratio is in the 1.5 to 3 range. Join your peers on the Internet's largest technical engineering professional community.It's easy to join and it's free.

gas molecule can evolve from liquid phase Retention time = Volume of liquid storage in vessel 3.

This article aims to present an overview of a simple explanation of a 3-phase separator. ! Table 4 shows Leff/D for three different vessel IDs.

All other variables/parameters are the same as the base case presented above. a !1AQa"q2B#$Rb34rC%Scs5&DTdEt6UeuF'Vfv7GWgw(8HXhx )9IYiy "(($#$% '+++,.3332-3333333333 continuous liquid-phase space height, in. The given values for Example 2 are listed next: Step 1.

*:JZjz ? Table 10.

Step 3.

Related equation that I found important have been attached in the spreadsheet. 5. Low liquid level height Table 11. Adobe d C If the liquid level is too high, the demister will not drain, and liquid siphoning can occur.

aH) T-PS Lets briefly look at the common design factors of a separator below. 4.